ervine

SRC Member-

Posts

3,334 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Everything posted by ervine

-

It's the belly button of a little grey alien!!! Quick get scully and mulder!!

-

Hm.. too nice and neat and clean for me...

-

sweet.... but the metal stand looks really skinny for such a huge tank!

-

Huh... only airstone driven skimmers need an air pump.. so yes, the movement of the water will naturally draw in the air... As for blades, I don't know how to explain it but it still moves water.. although it's notably less than if it were the fans... centrifugal action? shucks cannot remeber the term.. But anyways, the curving of the blades you mentioned (like a typical table fan) works when the movement of fluid is straight past the blades, for the case of centrifugal (not sure if I'm right) the movement is in and then out at 90 degrees.... something like that lah... Aiyah as long as it still moves water lah...

-

It's not so much the twisting, it's the constriction that matters. It's just I achieved that constriction with a simple twist. This constriction forces water to move at a higher velocity through the constriction, this higher velocity in turn sucks in air from the air intake.

-

No waves created in a fishtank could possibly break glass.... esp when we are talking about >6mm glass... same for silicone... Unless the waves carry some rocks with them I doubt anything will happen

-

You have to modify your pump to make it work with the needlewheel impeller, the air inlet for most (if not all) pumps comes at the outlet.. See the pics above... the venturi intake is not at the output but rather at the input...

-

anyway can go see this thread here http://www.sgreefclub.com/forum/index.php?...pic=15204&st=15 to have a look at the effectiveness of the impeller... don't wanna double post the results

-

See here... http://www.sgreefclub.com/forum/index.php?showtopic=14736 Basically it's a normal PVC tubing heated and twisted with a pliers until it starts to bottleneck... then simply drill a small hole just enough for the little air tubing elbow to go in and super glue it in place.. As for the connection to the pump, heat the tubing again and squeeze it till it moulds over the intake of the pump... completely no damage or modification to the pump for this part... The elbow is there coz it's part of my skimmer... so that part can ignore...

-

-

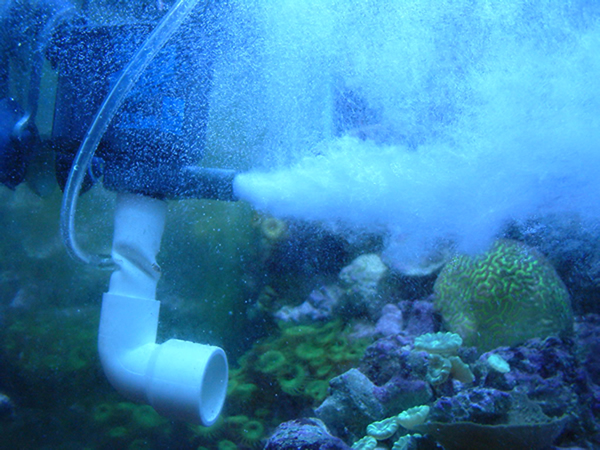

Here's a closer look at the bubble spray... note that I've managed to open the air intake all the way without the pump getting excessively noisy... something I could never do with the original impeller

-

Here's the view of my tank... width is 1.5ft so the modded MJ can still push enough water across this length and more...

-

before.. that's the whole point... so bubbles enter via venturi then further get chopped up by impeller... and water goes slower not faster... slower because the needle wheel is not as effective in moving water... check out the first few pics in my other thread here http://www.sgreefclub.com/forum/index.php?showtopic=14736

-

Hehe... maybe ah... toothpaste can help polish the little spikes a little...

-

Here's a pic of the DIYed needlewheel impeller using a $0.50 plastic brush... not very nicely cut but it get's the work done

-

Well basically for starters, most venturi driven skimmers get their bubbles solely from the venturi, which is often placed AFTER the impeller... In this case, the venturi is placed BEFORE the impeller... so when the bubbles hit the impeller it chops them up even more than what any venturi can do... In the case of a needlewheel impeller, it's "spikes" or protrusions work differently from a typical impeller which is meant to push water, this is meant to chop up air bubbles... Maybe this pic might help you see how the needlewheel can chop up water... it's my DIY needlewheel impeller.. not very nice but it gets the job done

-

Well... I gave the old skimmer the boot and went ahead with a more "secure" design... this monster stands 2.5ft tall with a mixing riser of 2ft... notice that I reused the collection cup and neck.. hehe too lazy to make a new one... once again leaks have occured in initial water testing.. but should be a lot easier to resolve than my previous skimmer...

-

i don't get how u use pvc to make the needles leh... doesn't matter lah.. whatever works... actually the bristles of the brush are quite stiff when they are so short... so no worries... in fact the original MJ impeller fins are soft too!

-

export out as jpg becomes black???? HMMmmmm... weird... not to sure liaos...

-

I think it's the way the chiller works right? I set it at 25 but it chills only to around 26... waits till it reads 27 or 28 then it kicks in again.. BTW, is yours the old or new series... wah madness the old series sounds like an aeroplane!!! any way to silence it?

-

hahaha... damn funny... good one

-

hey it works like a charm!!! In fact I can push a lot more air in than before without it starting to rattle insanely... Will post pics soon.. Digicam cable not with me...

-

i put on makeup for a video shoot before... wah lau I don't know how you girls can take it man... my skin was suffocating!!!! not to mention the breakouts I had the next day... yikes... luckily only did the concealer foundation or what lah... no eye liner, lipstick, eyeshadow etc etc... phew...

-

bad for me.. no transport back coz no bike nor car... shucks

-

if you want low res, play the video clip then when it's time to capture the image, press "Print screen" on your keyboard. Go to photoshop, click new, select ur desktop res, then paste... voila! Instant screenshot... but u have to crop.. If not can use premiere, import move, go to frame that you want, then export frame as an image... Hope this helps..