-

Posts

6,221 -

Joined

-

Last visited

-

Days Won

40

Content Type

Profiles

Forums

Gallery

Everything posted by sherman

-

Heat removal from LEDs is very important since their lifespan and performance depend on the operating temperature. When the temperature of the crystal increases from 25 to 100C the performance of the most heat tolerant LEDs (Luxeon Rebel ES royal blue) decreases by 10%. In the same time, less heat tolerant LEDs may lose up to 75% of their efficiency (Luxeon Rebel amber). This drop of efficiency is even more pronounced in LEDs from not well known manufacturers

-

Challenge number two: Battling the heat Modern LEDs are quite efficient at the conversion of electric energy into light. However, even the most efficient LEDs today waste about half of the consumed energy in the form of heat. Since the crystal is quite small (a power LED’s crystal usually has the surface of only 1-2mm2 or 0.0015-0.003in2), its generated heat density is quite large. In fact, it is about 30 times as large as the heat density through the soleplate of a household iron!

-

Tomorrow we look at the second issue. Battling the heat

-

Therefore, we believe that the best approach to avoid the Disco effect is through the use of individual LEDs packed tightly on a custom MCPCB. This way the light beams from differently colored LEDs will mix up well, without forming color shadows. The smaller is the distance between individual LEDs, and the better it will be able to overcome the color shade effect.The distance between individual LEDs, however, cannot be smaller than the size of secondary optics. Fortunately, compact and efficient LED lenses are available today. The best effect is achieved through the use of hybrid optics, combining a TIR lens and a special light diffusing material.

-

A better approach would be, instead of COBs, to use carefully selected individual LED emitters (the ones with most efficient bins, to minimize heat generation), then mounted on an advanced MCPCB to provide the best heat dissipation from the crystal. This can yield less than a 10°C temperature difference between the junction and the MCPCB, and about 12°C between junction and heatsink

-

Note that the thermal resistance of COBs from Asian manufacturers is usually even higher than those of Cree. This can result in serious overheating of the crystal (even though the heatsink temperature may stay in the acceptable range).

-

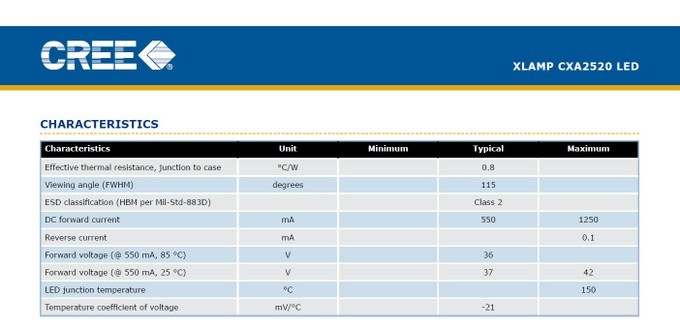

A shorter thermal path in COBs is usually listed as an advantage, however, this is not as simple as it seems. As an example, let us consider Cree’s newest COBs. As one of World’s top leaders in LED technologies, this company pays closest attention to improving the thermal characteristics of their products. According to the datasheets, thermal resistance of Cree’s COBs varies from 2.5°C/W for CXA1507 to an impressive 0.8°C/W for CXA2530. Seems to be pretty good, huh? Only until we notice that, say, CXA2530 may consume up to 50W of powerAccording to the datasheet (see the picture below), this will add a significant 40С to junction temperature above the temperature of the LED case. For CXA2530, with 61W power consumption, junction temperature will be even higher

-

Our second requirement – efficiency – would suffer. Theoretically, crystals from different manufacturers can be combined in one COB package, but this can be practically impossible for similar crystals, made by different brands. As a result, the COB will have to use crystals with significantly lower efficiency, compared with world’s leading manufacturers. Our calculations based on the datasheets from leading Taiwanese manufacturers :Epistar/Epileds, show that there can be as much as 54% difference in efficiency compared with best individual LEDs from top manufacturers.Even Cree declares about 34% less efficiency for their best COBs today, compared with individual LEDs

-

However we believe that COBs are not the best choice for a reef tank. Three factors are most important when building a reef fixture: spectrum, efficiency, and opticsNone of the top ranking manufacturers, neither Cree nor Philips Luxeon, cover the whole spectral range required for reef lighting. Cree, for example, does not make violet (“true actinic”), or deep red LEDs, Philips Luxeon also doesn’t cover the violet range. Of course, there are smaller companies which make a wider range of LEDs, and their crystals cover the required spectrum.

-

One option is to collect a group of LED crystals in a small space by creating a custom COB (Chips On Board) with many LED crystals closely packed in one case. A COB is a matrix of individual LED crystals attached to a common platform and covered by a protective compound (usually silicone). They have several advantages over SMD LEDs and are becoming quite widespread for general lighting use. Indeed, they are easy to mount, provide a relatively low cost per emitted light, and are undemanding to optics – they are, indeed, very good when you need lots of light from an inexpensive fixture. COBs can be very good for the lighting of roads, warehouses, or other large premises.

-

Challenge number one: Getting rid of color shadows (disco effect) The so-called disco effect is witnessed when a tank is lighted by several power LEDs (especially multi-colored) which are positioned on a certain distance between each other. Each LED is a point light source, resembling a small sun. When illuminated by several LEDs from different directions, every object produces multiple shadows. When these LEDs are of different color, these shades look colored like disco lights.The only way to overcome this effect is to place LED crystals as closely as possible. We cannot place all the LEDs of the fixture in one place, as we want to light up the whole surface more-or-less uniformly. Therefore, we need to gather all differently colored LEDs in groups, in the required proportion. These groups can then be evenly spread over tank’s surface

-

The second problem requires a complex of efforts to achieve an acceptable solution. Some people spot these color blotches at once, while others may require time to notice the problem. Still, it is very important to eliminate this effect, as it affects our perception of the reef tank directly.

-

The first problem is relatively easy to address by combination of LEDs of all spectrum in order to cover the desired spectrum fully (in our previous article we have shown that violet spectrum plays an important role but is neglected or poorly represented by most manufacturers, mainly due to the high cost).

-

It is almost impossible to accurately measure LEDs efficiency at home, and manufacturers are tempted to indicate a higher efficiency for the LEDs they use: serious errors in LED fixture specifications are common. We have heard claims from many experienced reef keepers that LED lighting has not yet matured for aquarium use. We believe that this notion is caused by two main shortcomings of the existing fixtures: spectrum deficiency and poor color mixing which results in multicolored blotches and shades. (Normal know as disco effect and shadow)

-

There are a few other important issues which are often poorly addressed in existing fixtures.We will look into them in another few days.We hope you digest and understand what manufacturers never tell you about led

-

In fact, this means that by choosing between two fixtures of same power but a three-times price difference, one may yield less light per dollar from the cheaper fixture .At the same time, the less efficient fixture will spend much more in power bills in a fixture’s lifetime.Worst of all, it is almost impossible to accurately measure LEDs efficiency at home, and manufacturers are tempted to indicate a higher efficiency for the LEDs they use.We believe that the choice of most efficient LEDs is very important when building a fixture. As we have shown, their higher cost will be justified in time.

-

If we compare low-cost Chinese LEDs, which now flood the market, with the best bins from the best manufacturers, there can easily be three a times efficiency difference, or even more!

-

There are many other advantages in using LEDs with better efficiency, which are far more difficult to account for objectively due to many unknown variable factors. To name a few, less efficient LEDs will result in higher junction temperature during operation, which in turn, will further reduce their light performance and result in a shorter lifespan of the LEDs. The heat from a less efficient fixture will be transferred to the environment, and it is more likely that the tank and the room will require a more powerful cooling unit.

-

Therefore, beware if a manufacturer only specifies that “the fixture is made with Cree LEDs.” without even specifying the particular LED type and the spectrum used - it is most probable that the fixture may be using LEDs which are two or even three generations old, which offer mediocre performance, at best.The cost of LED emitters is only about 20% of the total fixture cost, but this additional 20% expense can provide up to 40% extra light, and add an additional advantage, less heat generation and power consumption.

-

Thus, by installing less efficient LEDs in a “cheapo” fixture, it will yield 40% less light as compared with the use of best bin LEDs. Yet, at a glance both will seem to be utilizing the same LEDs.Of course, fixture manufacturers are tempted to use less efficient LEDs, since the best bin’s price can be twice as much as that of the worst bin. I don't know who like to pay the price of a Lamborghini and get a Suzuki or you pay for the price of a suzuki and you believe you can get a Lamborghini

-

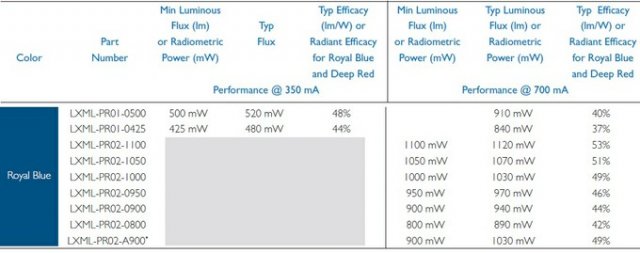

You can see that the efficiency of electric power conversion into light energy can vary from 37% to 53% for different bins at the same current. This means that the best bin is some 40% more efficient compared the worst bin!

-

The second binning category - luminosity or efficiency bins - is also very important. The manufacturers use this bin type to sort out their LEDs according to the optical power output, while the electric power consumption is the same. Even for the same LED type the difference in efficiency between bins may be significant. Let us have another look at the datasheet of same Luxeon Rebel ES Royal Blue (Fig 2).

-

The ability of the human eye to differentiate between close shades of color depends on the range. It varies from approximately 1 nm resolution in the blue-green and yellow wavelength ranges to about 10 nm or poorer for red and blue [1].It is easy to see that by looking at the bin code.LED emitter’s peak wavelength can vary significantly. Color bins can be very narrow, sometimes only 5nm wide or even less, and it is important to take this into consideration when we want the whole desired spectral range covered - otherwise we can miss some shades of color in our fixture’s light